Carbon Capture, Utilization and Storage, or CCUS, is a process that will allow industries that emit carbon dioxide (CO2) to both maintain their business plans and reduce CO2 emissions. First, it uses special equipment to remove the CO2 from their facilities’ exhaust before it reaches the air. Once captured, the CO2 can either be provided to companies for other uses or transported by pipeline to underground geologic formations certified for safe and permanent storage.

Pipelines have been safely transporting CO2 for more than 50 years. An expanded CO2 pipeline network can create new well-paying construction jobs and help sustain industrial jobs.

ExxonMobil Pipeline Company currently operates the largest network of CO2 pipelines in the U.S. It is supporting ExxonMobil Low Carbon Solutions' CCUS projects by helping build new pipeline segments connecting existing CO2 pipelines to additional storage sites.

Safety is Priority Number One for ExxonMobil Pipeline Company. We will meet or exceed regulatory requirements and industry best practices during construction. We also are committed to being good neighbors in the communities where we operate and responsible stewards of the environment through which our pipelines travel.

CO2 pipeline construction safety

CO2 pipeline construction safety

ExxonMobil Pipeline Company focuses on safety and quality assurance through every step of the construction process, from project planning and design, to the manufacture and transportation of pipe, assembly and lay-in of the pipeline, and ultimately system start-up and restoration of the right-of-way. Federal and state regulators periodically inspect the construction sites to certify construction regulations are being properly followed.

CO2 pipeline operations safety

CO2 pipeline operations safety

Current federal law and government pipeline safety regulation require carbon dioxide (CO2) pipeline operators to proactively inspect their pipelines and conduct preventive maintenance. CO2 pipelines are constructed with high-grade steel and a protective coating to help prevent corrosion. Once operational, the CO2 stream is specially treated before it is placed into the pipeline to remove impurities that could affect safe operations. Pipeline personnel maintain the safe operation of the pipelines, which are monitored 24/7.

Learn more about ExxonMobil Pipeline Company’s operations integrity management system.

Federal government pipeline safety requirements

Federal government pipeline safety requirements

- In the Pipeline Safety Reauthorization Act of 1988, Congress required the U.S. Department of Transportation (DOT) to regulate carbon dioxide (CO2) liquid pipelines.

- In 1989, the U.S. Department of Pipelines and Hazardous Materials Safety Administration (PHMSA) expanded its federal regulations for similar liquid pipeline systems, like crude oil and refined products, to also cover CO2 pipelines.

- PHMSA inspects and enforces compliance with potential fines on pipeline operators violating federal CO2 pipeline safety requirements.

CO2 pipeline safety record

CO2 pipeline safety record

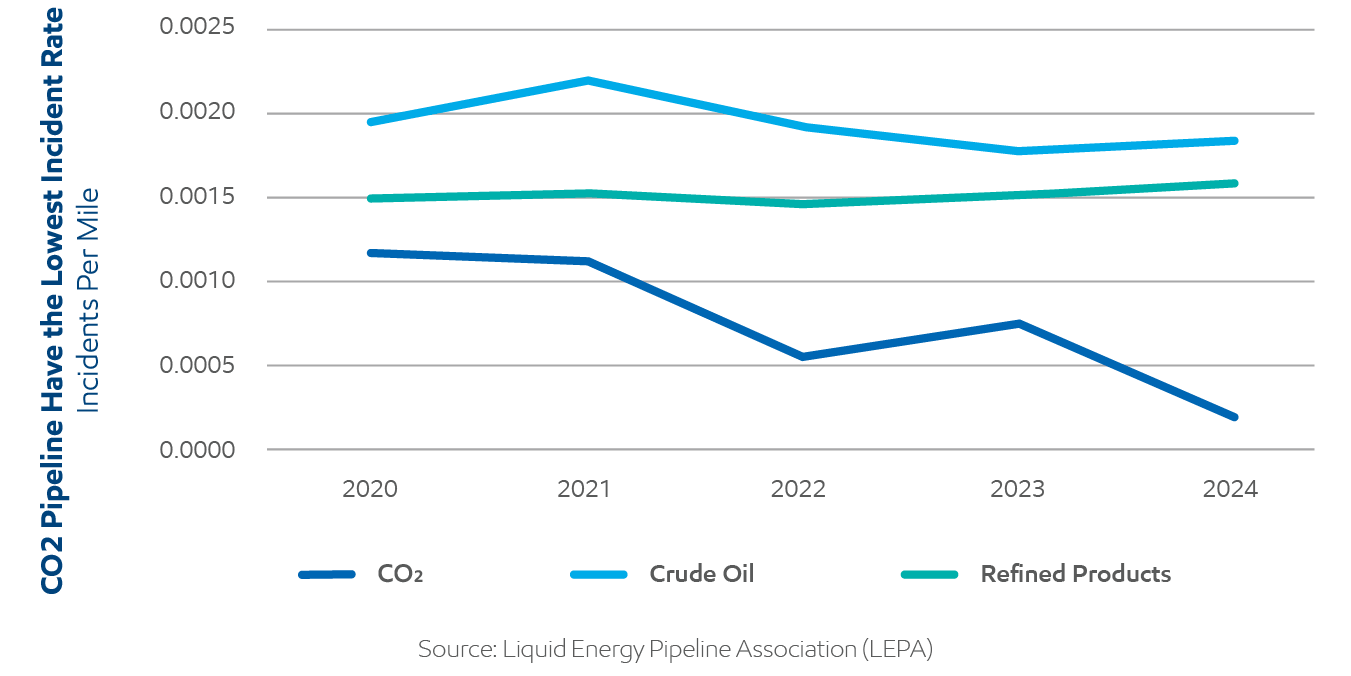

- Publicly available government pipeline safety data collected by PHMSA shows carbon dioxide (CO2) pipeline incidents are rare.

- CO2 pipelines have a lower incident rate than both crude oil and refined products pipelines, which are already low.

Why do we need more CO2 pipelines?

Why do we need more CO2 pipelines?

-

Storage:

North America has some of the largest known carbon dioxide (CO2) storage capabilities in the world – and produces a great amount of carbon emissions.

-

Lower-carbon energy future:

Achieving our lower-carbon energy future will require connecting these storage sites with the technology that captures the carbon emissions at their source.

-

Safest transport:

The safest, proven way to transport these captured emissions is by pipeline. CO2 has been transported safely by pipeline in the U.S. for decades, and currently there are more than 5,000 miles of CO2 pipelines operating in the U.S.

-

Benefits:

We will need to greatly expand this pipeline network to take advantage of the benefits CCUS promises our local communities, our heavy industries and our nation.

-

Past experience:

-

Present performance:

-

Future performance: